Capabilities

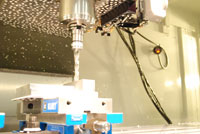

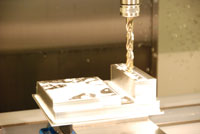

As North America's only professional pantograph manufacturer for light rail, G&Z has built an extensive portfolio of top quality pantographs, integrated control systems and accessories. Our pantograph technical parameters meet the international IEC standard and are adapted globally. Currently, we accquired ISO9001:2015 certification. With our state of the arts CNC equipment, all products are made in house according to customers' need.

Our CNC machines can create any customized parts and equipment tailored to your specific requirements. You can have the highest confidence in our expertise, repairs and precision parts leaving our shop as our Engineering team strives to provide optimal solutions, culminating in a product designed specifically for our customer.

Machine Information

HAAS VF-12 Vertical Mill

|

|

HAAS EC500 Horizontal Mill

|

|

HAAS DS-30Y Dual Spindle Lathe

|

|